Metal Stamping

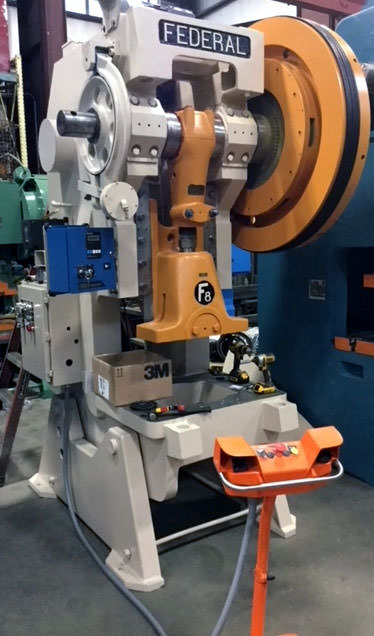

AMG has had a long-standing history in the stamping business. We utilize a wide variety of mechanical presses; both hand transfer and progressive style dies. Additionally, we have extensive punch press capability with a variety of equipment that includes, precision, high-speed ball bearing gibbed presses, automatic straight sided and OBI presses.

While the majority of our work contains ferrous materials, we also manufacture using a number of non-ferrous materials including, brass, copper, inconel, etc.

Progressive high-speed dies are a specialty of our staff engineers. Our ability to collaborate with customers on a design, proceed to build, and maintain dies also gives us the capability to expedite prototype development within our various product lines. We have recently started using 3D printers to become more competitive in prototype builds.

AMG Industries' capabilities include 20 stamping presses which range from eighteen to three hundred tons. AMG Industries maintains twelve straight-sided mechanical presses ranging from 60 to 300 tons. These presses are capable of running coil or hand-fed stampings. AMG Industries also has eight OBI mechanical presses for high-speed or bracket stampings. These presses range in size from 18 to 90 tons.

AMG Industries is a Lean Manufacturing facility practicing SMED and Just In Time delivery. AMG Industries' capabilities include Progressive dies, Compound dies, Draw dies, Flange, and Trim dies.

Why Choose AMG for

Metal Stamping

- Both Ferrous and Non Ferrous materials

- +/-.0005" on Dimensions in certain applications

- .010" to .250" material thickness

- Prototypes to Production quantities

- Engineering and Project management assistance

- Tool Design Support and Build capabilities

- Compressors

- Pumps

- Heavy Equipment

- Transportation

- Aerospace

- Electrical Power Generation and Distribution

Contact AMG

- (740) 397-4044

- 200 Commerce Drive - Mount Vernon - OH 43050

- sales@amgindustries.com

Start your project now!

Fill out the form below and we will be more than happy to get in touch with you.